Building Solutions from Butler

For more than 100 years, the name Butler® has been synonymous with building innovation. Butler offers virtually unlimited options for a building's appearance and functionality.

Speed and Efficiency with Building Systems - Pre-engineered steel building systems from Butler are widely regarded as the most efficient and effective construction method in the low-rise construction marketplace.

Eliminate Roof Leaks - The MR-24® Roof System is the most specified standing-seam metal roof system on the market, with more than 3 billion square feet installed worldwide. The MR-24® roof system has unique design features that accommodate roof movement under temperature swings and virtually eliminates roof leaks. Metal Construction Association Studies now estimate the minimum life cycle of a metal roof at 60 years!

Design Driven Building Solutions - Conventional or hybrid building designs come in any shape or size to meet the demands for any project. Your entire project can be designed, engineered, and manufactured by Butler to provide unlimited flexibility to fit your design needs. And, you can simplify your supply chain to make it more efficient and effective for your needs.

Save Energy - Reduce your total cost of ownership with tested assemblies from Butler. Their Guarded Hot Box provides in-place performance of U-Factors for roof, wall, and insulation system assemblies. You can easily meet the most stringent energy codes.

The Options Are Endless

Conventional Hybrid structural systems from Butler come in any shape or size to meet the demands for any project. You can simplify your supply chain by using Butler to design, engineer, and manufacture all your components, both conventional and pre-engineered. This unique flexibility gives you the ability to build a cost-effective, high performance building for any type of end-use. And there is no limit to the available exteriors, from standard metal walls to glass, brick, masonry, EIFS, or concrete.

Performance, Protection, Possibilities - Butler Roof Systems provide a complete system to meet the most critical concerns of architects, builders, and building owners. Butler's Retrofit Roof systems provide metal-over-metal or slope build-up options that are fully engineered to meet the requirements of the most stringent performance standards.

MR-24 Roof System by Butler Sets the Standard

Proprietary technology has established the MR-24 Roof System as the ideal solution for your next building project. Studies have shown that steel roof systems provide the industry's best life cycle value.

The Galvalume Service Life Report by the Metal Construction Association shows that the assumed building service life of a low-slope, steel standing-seam metal roof system is at 60 years as described in LEED, v4. The study on roofs in a variety of climate zones showed that a properly installed and maintained roof can easily achieve these life cycles.

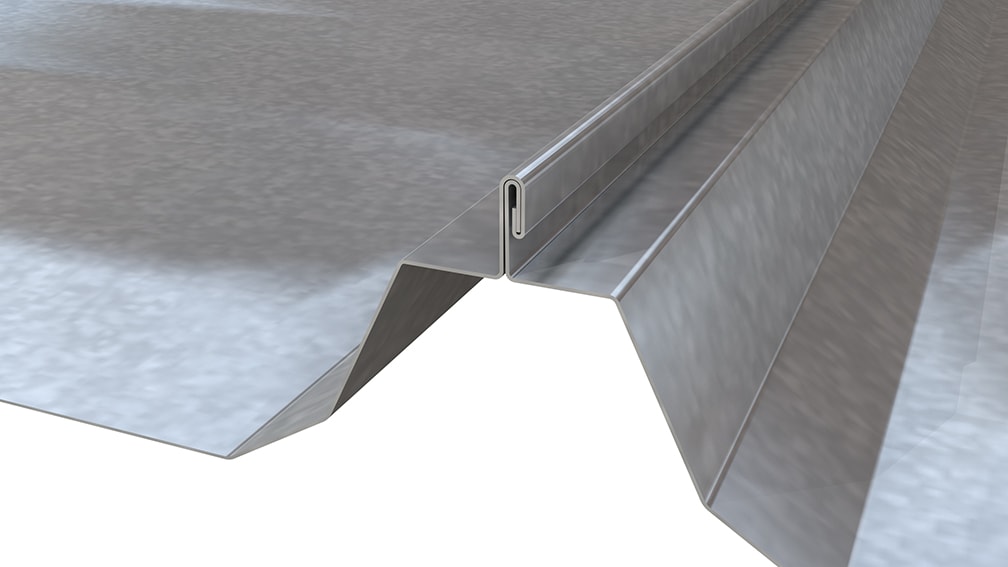

Moveable Roof Clip

The MR-24 Clip allows the roof to expand and contract with changing temperatures. This mobility prevents stress at the clips, fasteners, and panel splice that could otherwise make the building vulnerable to leaks and wind damage.

The Pittsburgh Double-Lock Seam

Only the MR-24 roof system seams are mechanically field-rolled to a complete 360-degree Pittsburgh double-lock seam. Other manufacturers simply crimp or snap the seams into place.

Perfect Alignment

All Roof panels and secondary structural members of the MR-24 Roof System are factory-punched to assure proper alignment and weathertightness.

Staggered Panel Splices

The MR-24 Roof System uses staggered panel splices to assure the proper seal and protect against future leaks. All splices are located over supporting steel members to reinforce vulnerable areas.

Wind UpLift Resistance

The MR-24 Roof System carries the highest UL wind uplift rating (Class 90). It has also been approved by FM Global as a Class 1 Panel roof, which may help lower your insurance costs.

An Attractive Combination of Quality and Affordability

Walls systems from Butler offer you a wide variety of finish options that go well beyond standard metal wall systems. Today's wall systems give you a rich appearance, and an appealing visual interest for any project with all the durability of a metal wall. And, tested assemblies from Butler give you the ability to meet today's stricter energy codes and reduce your operating costs.

Concealed Fastener Wall Systems

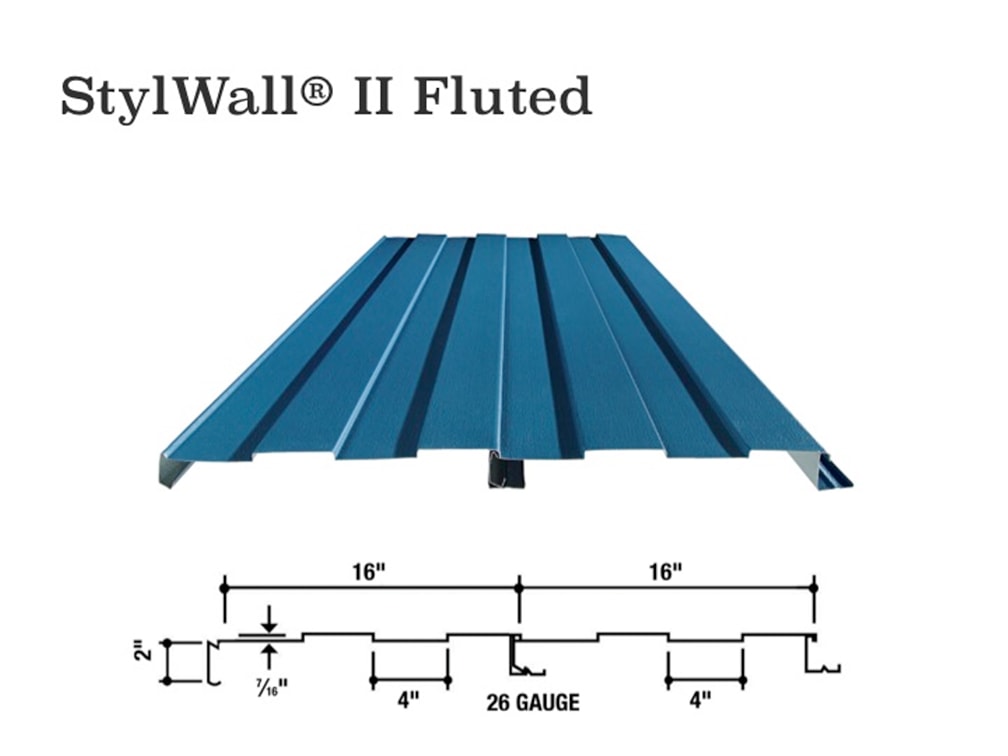

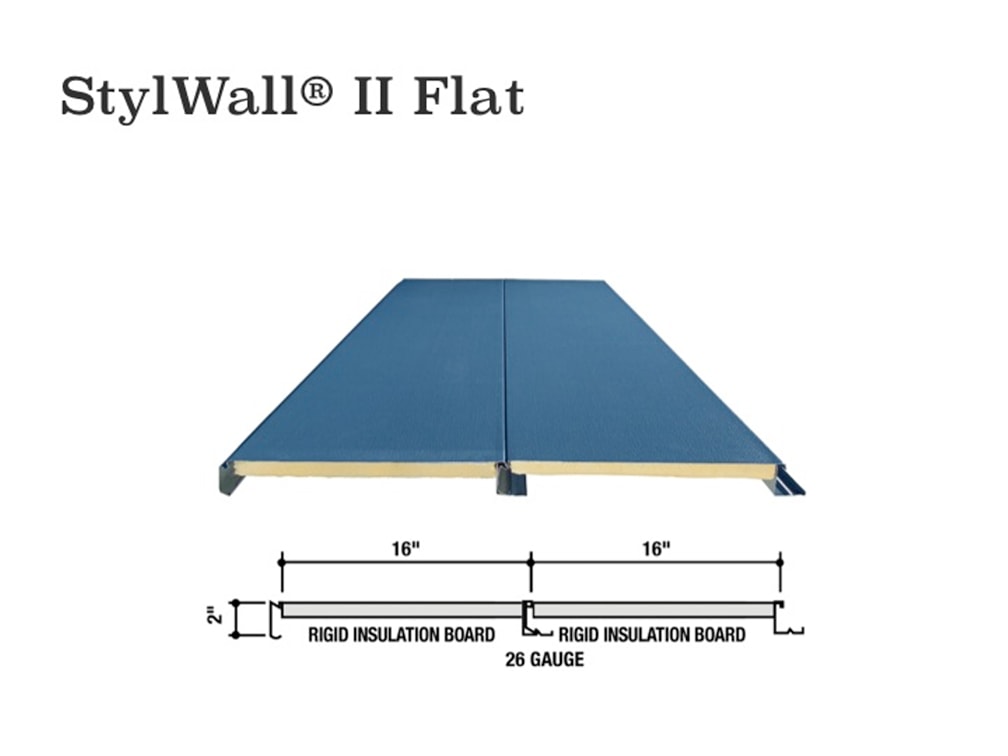

StylWall II Fluted and Flat Wall Systems*

Each panel is fastened to the wall structural system and then 'locked' into the adjacent panel, concealing the fasteners and enhancing the building's appearance.

- Fluted panels accommodate a variety of insulation systems

- Flat wall option includes rigid board insulation for increased energy efficiency

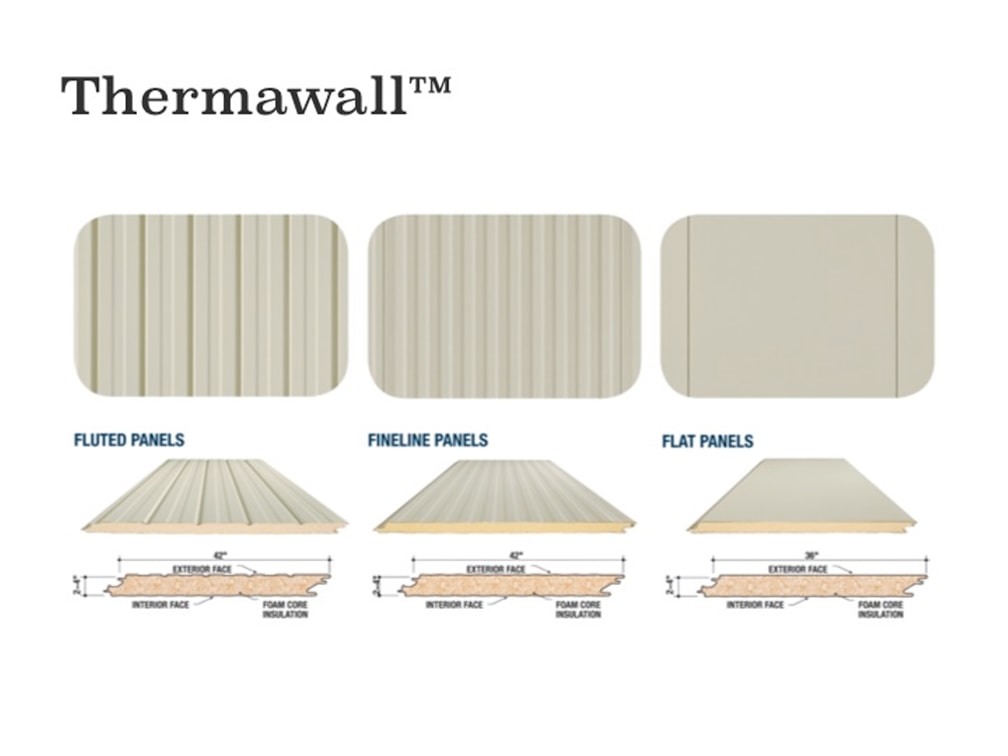

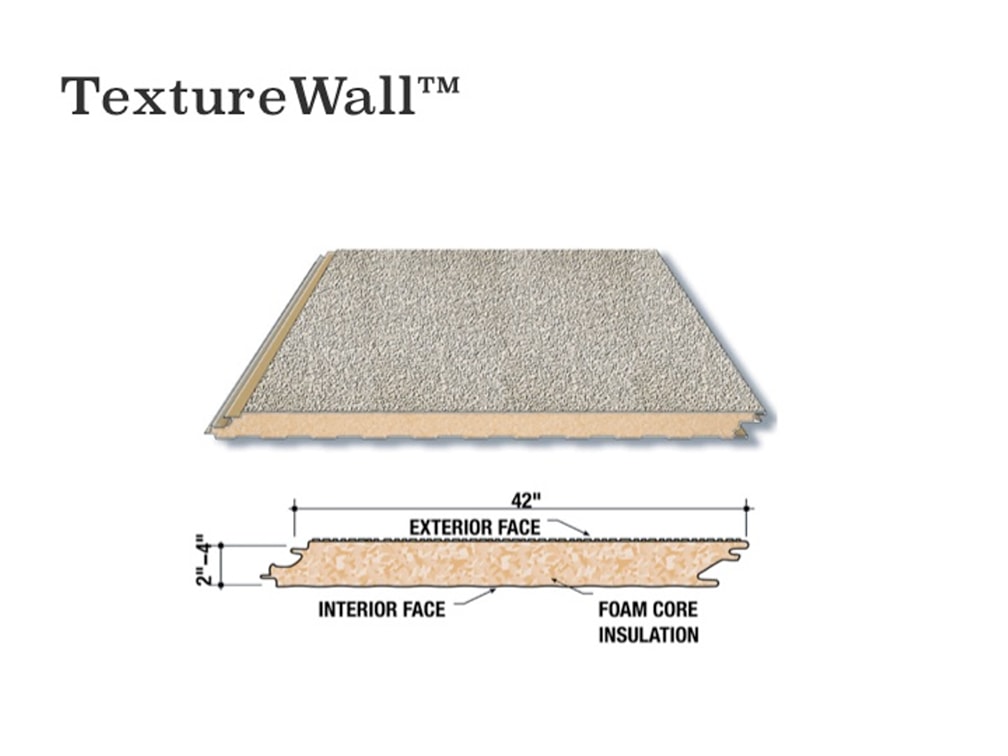

Insulated Metal Panels

Butler's Thermawall and Texturewall Wall Systems are factory-fabricated composite insulated metal wall systems with concealed fasteners for a clean and attractive appearance.

- Panel thickness of 2-4" to deliver excellent energy efficiency

- Texturewall creates a stucco appearance to give you all the aesthetic benefits of a masonry with all the durability of a metal wall.

- Simple installation that can be accomplished in virtually any weather condition

- Features a full 10-year warranty

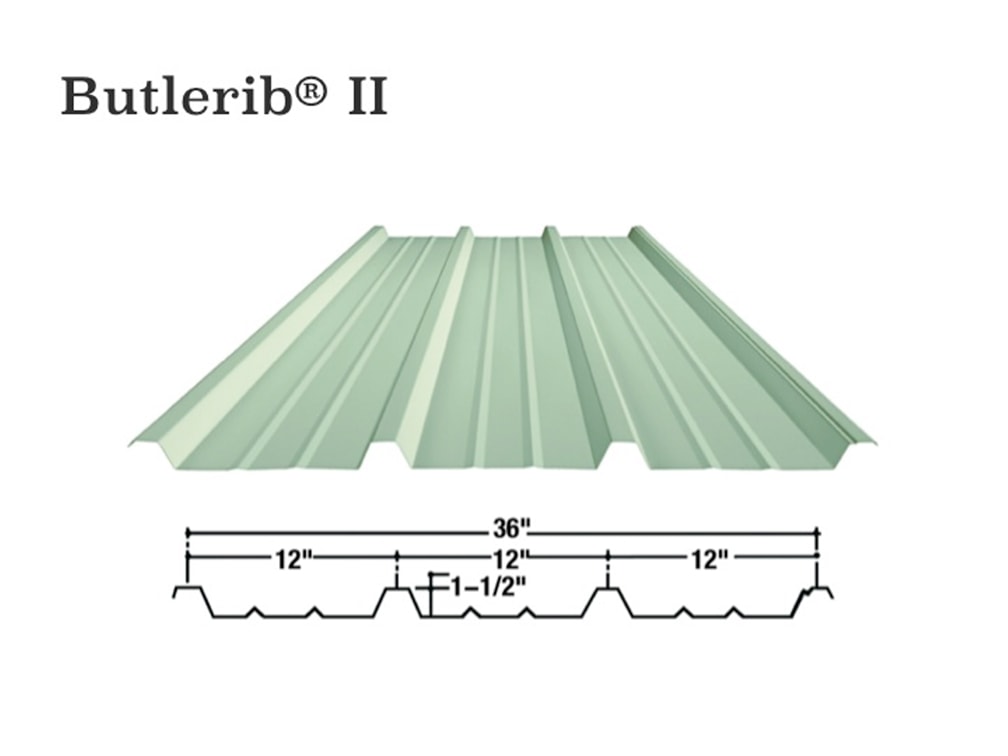

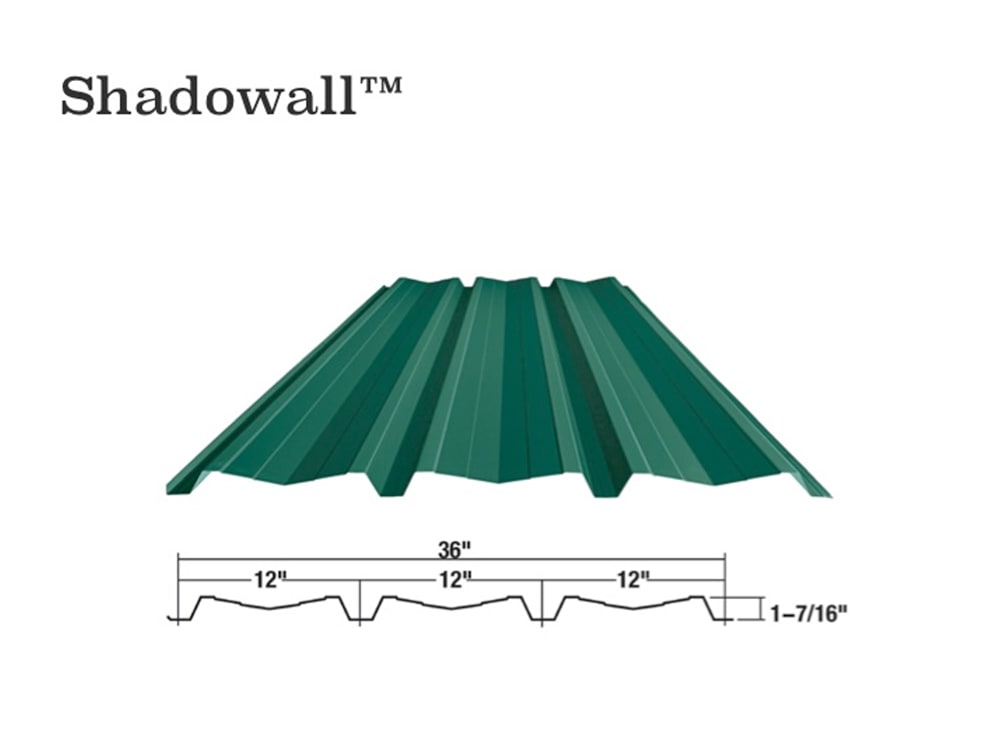

Standard Wall Systems

Shadowall* and Butlerib II wall systems are designed to create architecturally pleasing exteriors that are easy to install.

- Available factory punching assures fast and accurate installation

- Pre-designed transition materials coordinate with other building materials, windows and doors

- Shadowall is ideal for added insulation for enhanced energy efficiency

*Available in ewall systems for added insulation value to meet stricter energy codes.

A History of Innovation

Since its incorporation in 1902, Butler Manufacturing has believed that the foundation of their success lies in their research and development. Butler was the first company to successfully develop a pre-engineered, rigid frame metal building. Butler's MR-24 Roof System has dominated the industry since 1969, with more than 3 billion square feet installed worldwide.

Today, Butler's commitment to research remains as strong as ever. Their focus in recent years has been in the area of energy efficiency. Butler remains the only manufacturer in the industry to own and operate a Guarded Hot Box. The Guarded Hot Box can test actual 8'x10' roof or wall sections, assembled just as they would be on your building, to provide extremely accurate estimates of your building's heating and cooling energy consumption. Having tested assemblies allows you to meet today's most stringent energy codes using standard Butler materials to reduce your in-place construction costs.

Studies have shown that only 10% of a building's lifetime cost is in the initial construction budget. 90% of the total cost of building ownership is in the operating budget to pay for lighting, heating, cooling, and maintenance. Considering the impact of operating costs in the pre-construction stage allows you to focus on the total building operating cost.

Facility Builders & Erectors, Inc. is proud to partner with Butler Manufacturing.